Before fitting a new turbo, it’s essential to find and eliminate the root cause of a previous damage.

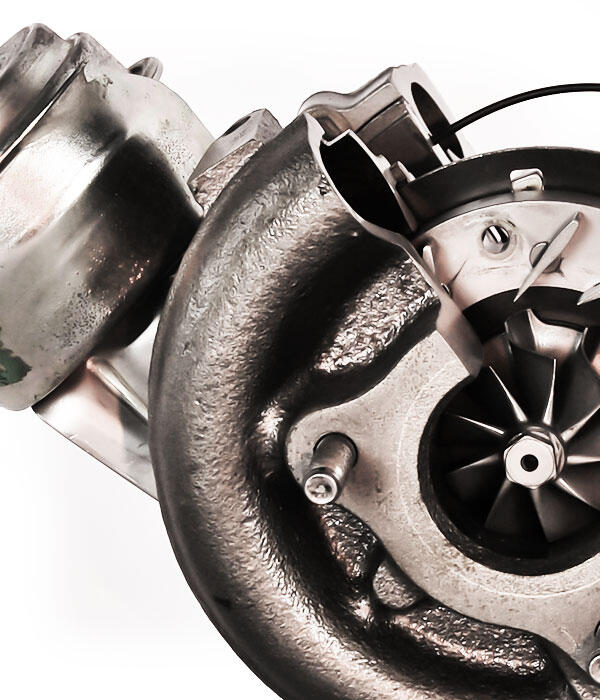

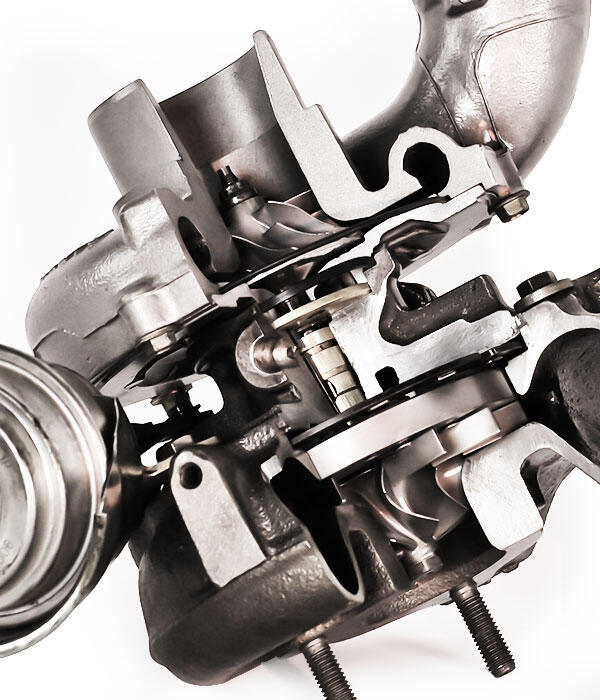

A turbocharger is a complicated and technically advanced device made with an extreme precision. Incorrect use or any modifications made may lead to its damage. It’s essential to find the root cause of the failure and eliminate it before installing a new turbocharger.

When replacing a turbocharger, it’s obligatory to do the followings:

• Make a precise check of the air intake system and if necessary, clean the engine intake manifold. The next step is to replace the air filter. Be aware that any contaminants in the intake system can cause turbocharger damage.

• You should always use only components recommended by the OE manufacturers.

• The oil system must be correctly diagnosed for any leaks and blockage in order to ensure the proper oil flow throughout the entire turbocharger lubrication system according to engine manufacturer’s specification.

The oil feed line should always be replaced with a new one, due to the difficulties connected to a proper inspection of possible blockage and inability of effective cleaning it. We highly recommend to use the new Evoron oil feed lines.

The oil flow may be drastically reduced by the blockage of the oil feed lines, especially by carbon deposits from the combustion process. Lack of proper lubrication is one of the main reasons for turbocharger damage.

• Check the condition of the oil gaskets, oil feed and drain lines in the turbocharger lubrication system. In case of any contamination or damage, they should be replaced.

• It is obligatory to change the engine oil and oil filter.

• While mounting the new turbocharger to the exhaust manifold, use only dedicated mounting kits. We recommend to use Evoron mounting kit. The connecting screws should be tightened with a correct torque, according to the engine manufacturer’s specification.

• Examine and if necessary clean the engine exhaust manifold. Foreign objects in the manifold may cause turbocharger damage.

• After fitting an oil drain line, fill up the turbocharger oil feed hole with clean engine oil. At the same time manually rotate the turbine wheel.

• After connecting all the turbocharger components, crank the engine for 10-15 seconds without starting the engine or start the engine for just a few seconds to fill the oil pressure lines and turbocharger with oil.

• After start-up of the engine, it should be let idle for tens of seconds without applying load. Next check that all air, gas and oil line connections are correctly tightened and free of any leaks.

• Finally re-check the engine oil level.